& does relevant recommendations: 【 foraged rubber joint, heat pipe expansion, pine set limit to pull expansion 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

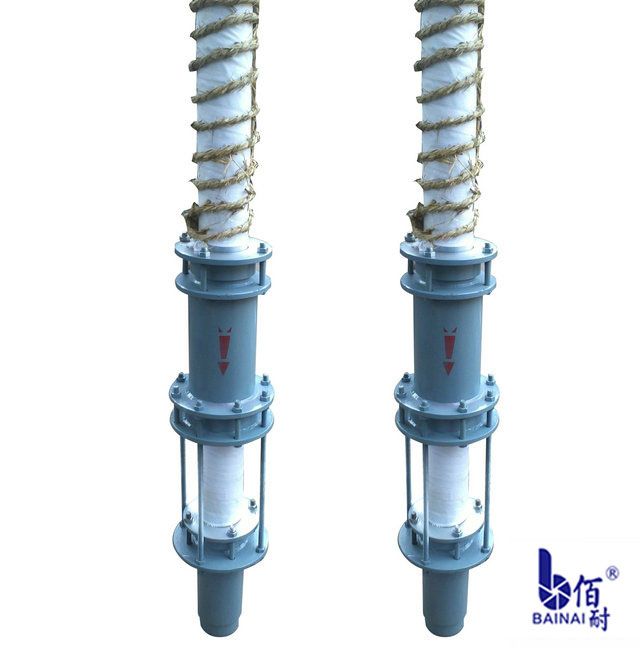

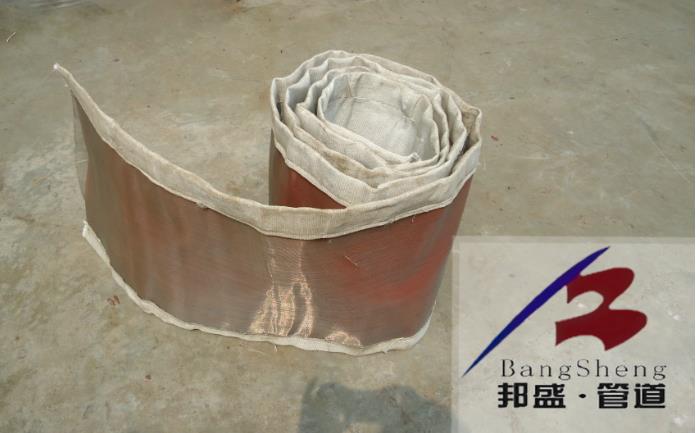

Non-metallic desulfurization ring of the skin

Non-metallic desulfurization skin is widely used steel mills such as desulfurization system in power plant an important part of a non-metallic expansion joint. At present, in response to the environmental protection need, each big power plants built the desulfurization system. Desulfurization of flue temperature change is big, strong corrosion and production of the characteristics of simple, convenient and irregular expansion, and so on the choice of expansion joint selection of nonmetal expansion joint. Desulfurization system non-metallic compensator skin ring are our professional and technical personnel for wet flue gas desulfurization equipment corrosion, heat resistance, sealing and other harsh conditions to develop the latest products.

The characteristics of the non-metallic desulfurization ring of skin

In non-metallic expansion joint for desulphurization, besides S02 and S03 and desulfurization process of flue gas generally contain strong corrosive substance, such as hydrogen fluoride and chloride corrosion is a kind of high strength, permeability is strong, and more difficult to prevent low temperature humidity type dilute acid corrosion condition. After the desulfurization of flue gas temperature, generally between 40 ℃ and 50 ℃, and the humidity is very big and in a saturated state. According to the characteristics of flue gas, which is lower than the temperature of the flue gas condensation, easy cold flue gas condensation dew and corrosive liquid liquid water in damp environment. In this highly corrosive environment, desulfurization nonmetal skin need to use high temperature resistant corrosion resistant material.After years of engineering practice, we use can be highly resistant to acid and alkali fluorine tape and composite materials such as ptfe membrane to make non-metallic compensator rigging, greatly improving the service life of product. In addition, in low temperature of the flue non-metallic expansion joint, the need to use acid water in the drain non-metallic compensator to promptly eliminate, non-metallic skin can greatly increase the acid proof of life.

Non-metallic desulfurization ring skin material selection

1. Fluorine adhesive 1.4

2. Four fluorine membrane 0.3

3. Glass fiber cloth is 1.2

4. Four fluorine membrane 0.3

5. Glass fiber cloth is 1.2

6. Fluorine adhesive 1.4