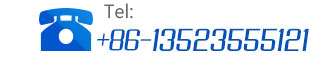

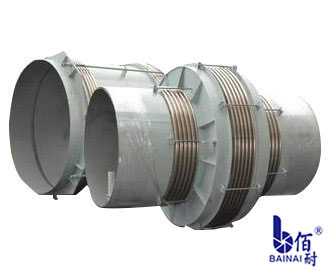

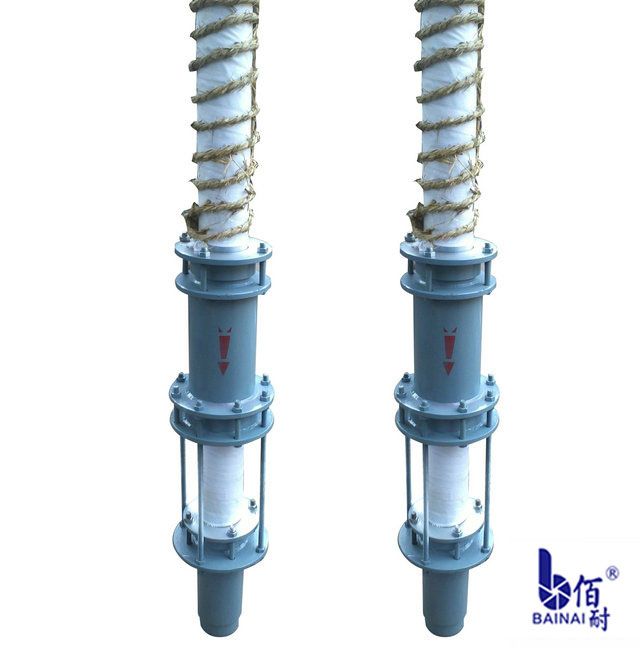

There are many kinds of non-thrust compensators. Today, Hongsheng will give you a detailed understanding of ZTW DC dielectric non-thrust compensator and bidirectional non-thrust sleeve compensator. If you are interested, please continue to look down.~ ZTW DC dielectric thrust-free compensator features: The thrust-free compensator uses Pascal's theory in fluid science and ingeniously uses a closed annular steam chamber in design structure. There are two annular pressure surfaces in the chamber, one is the fixed inner end face of the car, the other is the shoulder annular surface of the telescopic tube, which is closed in the steam chamber. The telescopic tube is movable with the telescopic tube. The area of the movable annular compression surface is exactly equal to the cross-section area of the telescopic tube. When the compensator works, the pressure on the annular surface and the cross-section area of the telescopic tube are equal under the action of medium pressure, but in the opposite direction, so Liang Yali counteracts each other. In this way, only the friction of the compensator packing is considered in the design of the bracket. In the calculation of the thrust of the fixed bracket, the thrust of the fixed bracket caused by the working medium pressure is no longer calculated. Therefore, the fixed bracket belongs to the load-reducing bracket, which can save a lot of bracket materials and manpower and financial resources. Characteristics of two-way thrust-free sleeve compensator: No matter which end of the compensator the medium flows into, the sliding sleeve at both ends of the compensator always slides freely to achieve the function of bidirectional compensation and increase the compensation amount. The inner sleeve of the two-way thrust-free sleeve compensator is connected with the pipeline. The principle and structure of high performance self-pressure dynamic seal are adopted. It can slide freely in the outer shell with the expansion of the pipeline and can meet the sealing requirements of any pipeline. A new type of synthetic material is used to seal the shell and the inner cylinder, which can resist high temperature, corrosion and aging. The skill ensures the axial East China, and also ensures that the medium inside the tube does not leak. Bidirectional non-thrust sleeve compensator is a compensating device for thermal fluid pipeline. It is mainly used to compensate the axial thermal expansion displacement after the auxiliary installation of linear pipeline. It is a compensator directly installed in any one-way or multi-way fluid pipeline without corrosion in tree holes. Two-way non-thrust sleeve compensator is widely used in transportation pipelines of urban heating, metallurgy, mining, power generation, petrochemical, construction and other industries. The service life of two-way thrust-free sleeve compensator is long, and its fatigue life is equivalent to that of pipeline. The sliding surface is specially treated and has good corrosion resistance in brine, rock solution and other environments. At the same time, if the sealing effect is weakened due to wear after many years, the flange can be tightened again to enhance the sealing performance. The bolt can also be loosened, the pressure ring can be removed, and then one or two layers of sealing ring can be installed to tighten the pressure ring and continue to use. Over the past few years, our Gongyi Hongsheng Pipeline Equipment Co., Ltd. has continuously developed new products, improved product quality, done a lot of research and experiments, put forward a new product structure, greatly improved the performance of the products, and won the praise of the vast number of users. If special specifications of products are needed, they can be designed and manufactured according to user's requirements. And sincerely hope that new and old customers, design units recommend the use of our company's products.