& does relevant recommendations: 【 foraged rubber joint, the flexible rubber joint, corrugated expansion 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

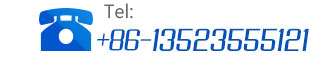

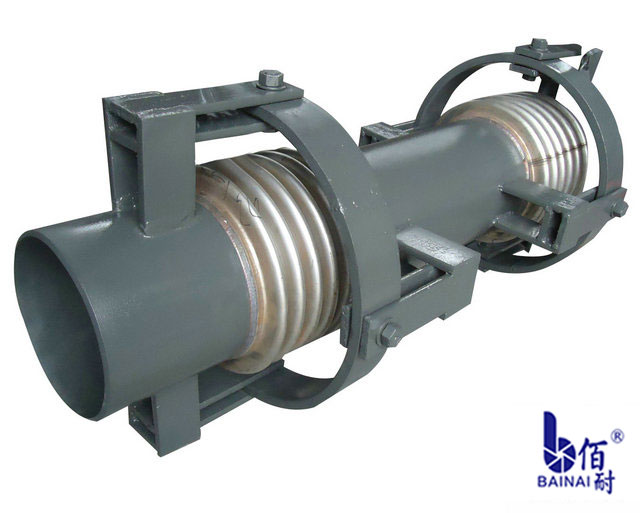

Double hinged compensator is introduced

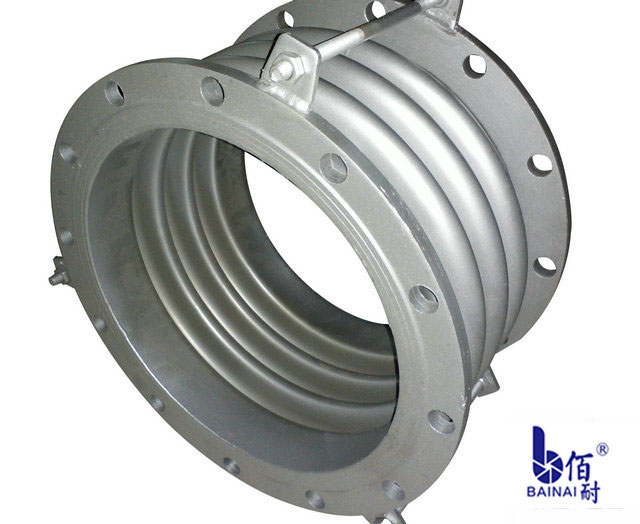

Double hinged compensator is made up of two identical wave tube and the tube, vertical plate and plate, flexible parts of pin, is suitable for the angular displacement of the compensation.

Special features: good elasticity

Execution standard: GB/T12777-99

Material: stainless steel

Shape classification: corrugated compensator

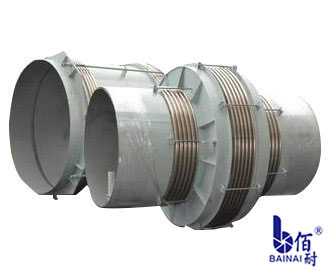

Connection mode: 1, flange connection; 2, to take over the connection

Products Angle to the compensation amount, plus or minus 4 degrees - + 9 degrees

Double hinged compensator installation and use requirements

1, double hinged compensator before installation should check its type, specification and pipeline configuration, must comply with the design requirements.

2, with inner sleeve compensator should pay attention to the inner sleeve of the bobbin in the direction of the flow in the same direction with the media, the hinge of double hinge type compensator rotational plane should be consistent with the rotational plane displacement.

3, need to be "cold" tight compensator, predeformation auxiliary components should be used in pipe installation is removed.

4, it is forbidden to use corrugated compensator deformation method to adjust the pipeline installation error, so as not to affect the normal function of the compensator, reduce the service life and increase of piping, equipment, supporting structure load.

5, the installation process, do not allow the welding slag splash to the shell surface, do not allow the wave shell by other mechanical damage.

6, piping installation has been completed, should be removed as soon as possible on the corrugated compensator is used as the installation of transport yellow auxiliary positioning components and fasteners, and dispatch spacing device according to the requirements of design to the regulation, make the piping have ample compensation ability under the environmental conditions.

7, compensator all active components shall be external components are stuck or limit the scope of its activity, should guarantee the active parts of normal movement.

8, when the water pressure test, coping with a compensator pipe terminal time of the department of fixed frame for reinforcement, make line do not move or rotate. For gas medium compensator and the connecting line, must pay attention to the water filling whether need to add temporary support. Hydrostatic test water cleaning fluid 96 chloride ion content is not more than 25 PPM.

9, after the water pressure test, as soon as possible the water wave shell, shell surface dry and quickly will wave.

10 and in contact with the compensator bellows heat preservation materials should not contain chlorine.