& does relevant recommendations: 【 pine set limit expansion pipe, steel expansion, flexible joint 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

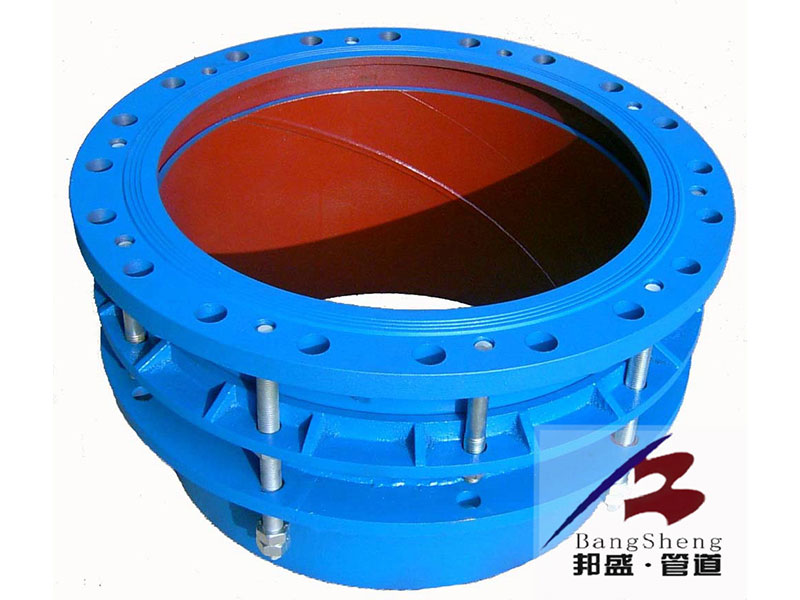

S313 expansion valve is introduced

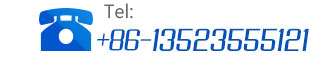

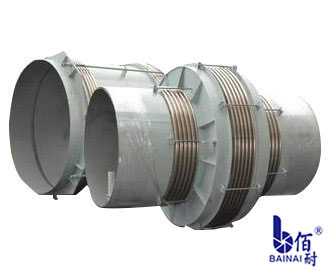

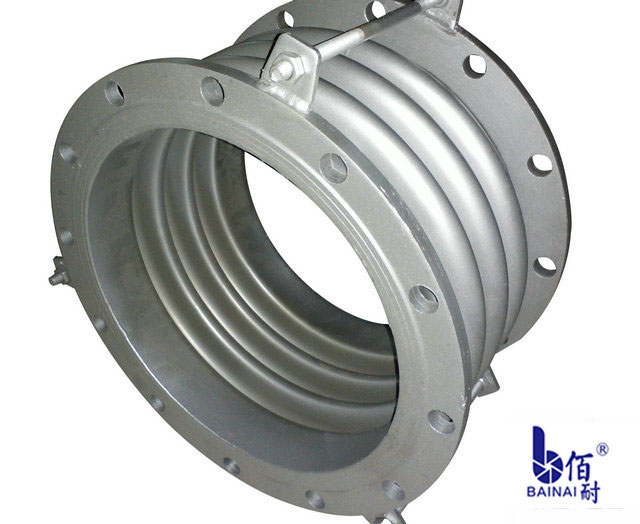

S313 expansion valve is also called the slip joint, expansion joint, compensator. Expansion in a certain range can be axial expansion, can overcome the pipe is not within an Angle of axial offset, can greatly convenient valve pipe installation and disassembly, free expansion in the pipeline allows expansion amount, once across its biggest ACTS as expansion amount limit, to ensure the safe operation of pipeline.

Expansion mainly to ensure the safe operation of the pipeline, and has the following functions: compensation Angle to the absorption pipeline axial, lateral, thermal deformation; Vibration absorption equipment, reduce equipment vibration influence on pipeline; Absorb the earthquake, subsidence deformation of pipeline. Bushing expansion for various water supply and drainage pipeline, the installation of a water tower, water pump, water meter, valve conversion provides great convenience, for long distance pipeline due to temperature difference expansion has played a very good regulatory role.

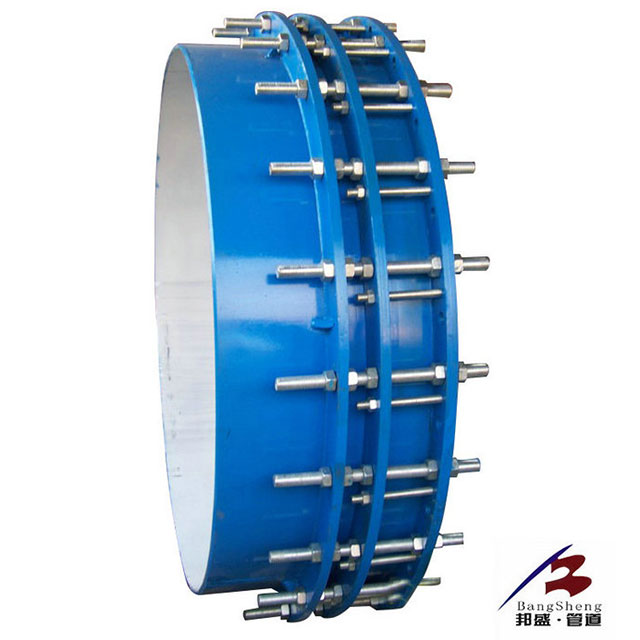

S313 expansion valve installation considerations

1. The installation should be between the maximum and minimum length, root tree actual situation can be adjusted.

2. When installation, loosen the packing pressure plate bolt, adjust the installation length, and ends with the pipe (or valves, water meter) installed according to design requirements, to check whether the packing is good, the pressure on the packing pressure plate, screw down the bolt by diagonal method do not partial pressure, make it stop leakage.

3. The expansion pipe installation after the check valve.

4. The expansion pipe ends must be set piers, it itself is not under axial tension, and prevent pulled off when necessary.