& does relevant recommendations: 【 pine set limit expansion, in a flexible rubber joint, cast iron expansion 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官方下载1.jpg)

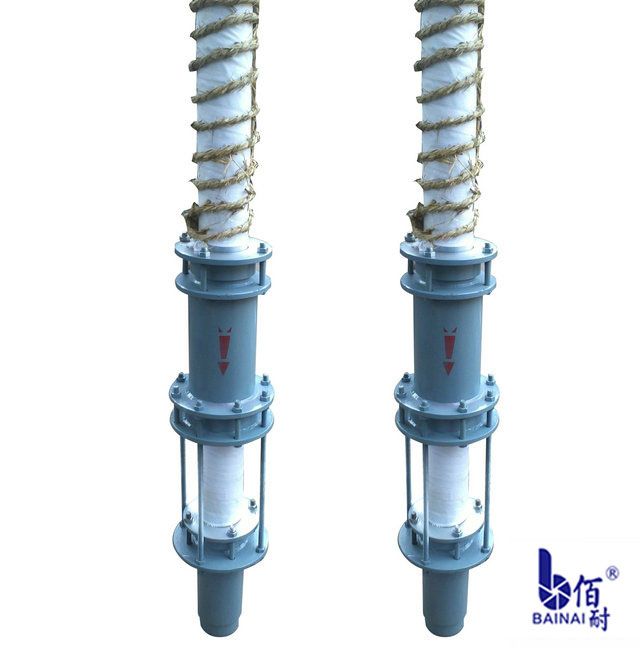

Compound injection filling type sleeve compensator is introduced

Compound injection filling type sleeve compensator is through the sliding movement of the sliding sleeve external sleeve, compensation of thermal expansion.

Compound injection filling type sleeve compensator installation requirements

1, compensator installation time, first check whether the specification is consistent with the order.

2, unidirectional sliding sleeve compensator should be installed in the medium into the side.

3, with compensator on both ends of the welding groove processing section must, after welding specification according to acceptance of hydraulic experiment, pressure is 1.5 times of working pressure. When pressure testing such as leak sealing device, should tighten bolt, tighten until no leaks.

4, compensator along the center line of the pipeline installation, alignment is more than 1%, in case of a runtime friction force is too large, and affect the sealing.

5, in the near the compensator of the pipe should be set up guided sliding support, to prevent the lateral displacement.

Six, pay attention to protect sliding surface, it is forbidden to touch or corrosion.

7, two-way compensator outer sleeve used the fixed support and maintain with concentric tube, on both sides of the compensation to approximately the same distance.

8, compensator under various temperatures, which can be installed according to the maximum length Lmax without pretension or preloading (materials to the maximum length of the products).