& does relevant recommendations: 【 pine set limit expansion, in a flexible rubber joint, duct compensator 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

官方下载.jpg)

Dc medium thrust compensator is introduced

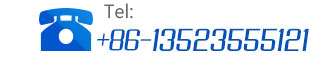

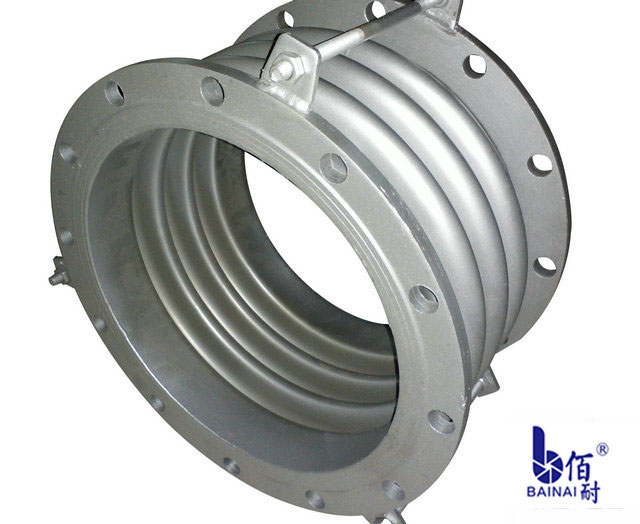

Compensator is also called the expansion joint, or the slip joint. By work constitute the main body of the corrugated pipe (a kind of elastic element) and the end of tubes, stents, flange, pipe and other accessories.

Belongs to a kind of compensation components. Use its work subject bellows telescopic deformation effectively, to absorb piping, pipe, container, etc is produced by the reason of heat bilges cold shrink and the size of the change, or compensation pipeline, pipe, container, etc. The axial, lateral and angular displacement. Can also be used for noise reduction vibration reduction. Widely used in modern industry.

Compensator is also known as expansion, expansion joint, corrugated compensator. Compensator is divided into: corrugated compensator, sleeve compensator, rotating compensator, natural compensator and so on several big square type, including ?

1. The compensation Angle to the absorption pipeline axial, lateral, thermal deformation.

2. Corrugated compensator expansion amount, valve pipe installation and removal.

3. The vibration absorption equipment, reduce the influence of equipment vibration on pipeline.

4. Absorb the earthquake, subsidence deformation of pipeline.

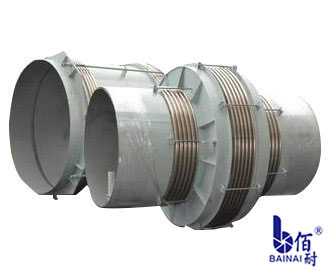

Overview of dc medium thrust compensator

The coming of the zero thrust compensator is heat pipe compensator is the product of a breakthrough progress. It not only opened a new field for the compensator of production, more important is that it not only solve the thrust Achilles' heel of the working medium inside the pipeline, but also solves the by-pass pipe type zero thrust compensator stress concentration, medium resistance big drawbacks.

At home in the near future, produce the LTW high temperature plugging agent, its heat resistance 30 o - 600 ℃, work pressure limit is 10 mpa. Gongyi city chenguang bellows company applying high temperature plugging agent on the compensator, the once-through no thrust compensator,Restructured into oil type dc medium without thrust compensator, solved the compensator is working for a long time, tiny leakage problems. Gongyi city light corrugated pipe company will LTW high temperature plugging agents, with 60 mpa. High pressure injection gun, injecting the oil to the packing room, make the packing material and indoor pressure, diameter and pipe diameter no capillary oil itself, and the nature of the heat bilges cold shrink, hence the compensator in the long-term work, not have leakage.

TWB and ZTWB type series oil type dc medium without thrust compensator, can be widely used in chemical, oil, thermal power, metallurgy, urban centralized heating pipe network, such as cooking and overhead pipeline. At the same time, is advantageous for the pipeline design, easy installation, and save a large number of funds (only a fixed stent costs more than 60%).

At present, ZTWB and TWB series oil type dc medium without thrust compensator, proved by users, its advantage has been preliminarily proved that is superior to other similar products.

The working principle of dc medium thrust compensator

The thrust compensator, PASCAL in the use of fluid mechanics theory, on the design structure is clever use of a circular dome, the steam room has two annular pressure surface, respectively a steam room is fixed ends, another is closed in the steam room expansion pipe shoulder ring surface, along with the extension tube are mobile. Compression of the movable ring surface area and telescopic tube cross-sectional area equal, compensator, under the action of medium pressure, annular pressure and telescopic tube on the surface of the pressure of the cross-sectional area is equal, but in the opposite direction, so both pressure offset each other. Thus, in the design of scaffold of only considering the friction compensator compression packing, push ? of fixed bracket

Dc medium without thrust as the main technical parameters of the compensator

(1) the nominal pipe diameter range

DN25-1000 - mm

(2) apply the nominal pressure range

PN acuities were 2.5 MPa

(3) applicable working temperature

T 350 ℃ or less

(4) scale

(5) the choice of the compensator

Choosing a compensator, the nominal diameter DN shall prevail, the design should be the same as the parameter in the table outside diameter pipe diameter, the margin of error of 3 mm or less.

Choose the compensator should be according to the following example indicate the model.

Note: material code: bx cr18n19ti, representing the whole stainless steel 1 T on behalf of the carbon steel Q235 - A, BXB represent half of stainless steel (extension tube 1 crl8n19ti)

Dc medium thrust compensator parameter list

官方下载的参数表.jpg)

Dc medium without thrust compensator installation requirements

(1) with the compensator on both ends of the welding section thickness of 6 mm or higher, groove processing, must be conducted according to the requirement of hydraulic leak test after welding.

(2) the sliding bracket and fixed bracket according to the design and installation, use ZTWB type, besides don't calculate work medium pressure thrust, the rest is the same. To ensure that the pipeline without lateral displacement, and along the axial expansion, compensator in general should be installed on both ends guided sliding bracket, the pipe bend, must install a fixed bracket.

(3) compensator insulation protection structure with pipeline route, but the extension tube telescopic part, do not produce binding.

(4) the compensator under various environment temperature, can be installed according to the maximum length LMax to, do not need to be stretched or compressed.