& does relevant recommendations: 【 reducing rubber joints, flexible rubber joint, direct buried corrugated compensator 】 is gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

The structure of the rotary expansion difference without maintenance

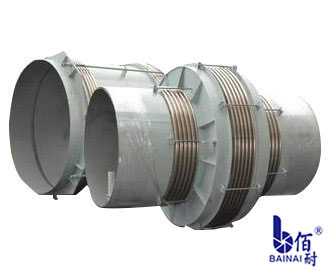

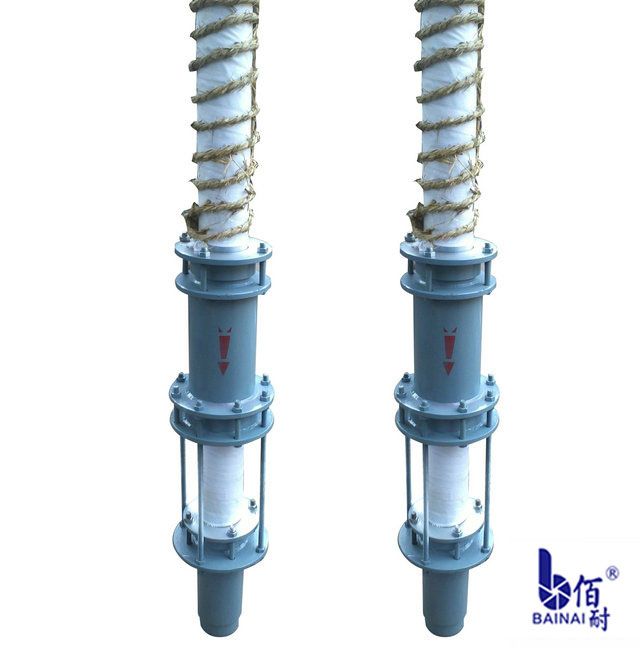

Maintenance-free rotating compensator: 1. No thrust by variable diameter pipe, casing, seal coat, flexible graphite packing in N, nut, bolt pressure spring assembly, packing gland, and the spring compression flange: described packing pressure between flange and pressure on the flange with compression spring, compression flange longitudinal section of u-shaped slot. Within the circle of u-shaped groove and the right end face of catheter between two fixed ring has to match the variable diameter pipe movement of ring rolling ball type.

2. Rotating compensator: by variable diameter pipe, casing, seal coat in, flexible graphite packing, nut bolts pressure spring assembly, packing gland, and equipped with corresponding ball.

Maintenance free rotation compensation valued quantity 1/3, structure have obvious difference.

The working principle of rotary expansion and maintenance-free

Maintenance-free rotating compensator and rotating compensator products are used by flexible packing cavity packing seal. Every revolution of the products in use process packing will wear a bit, when the wear reaches a certain value, the amount of the product would be a leak. Rotating compensator must be heat pipeline gas, the filler pressure flange, add a certain amount of filler, compression flange again, restore use;And maintenance-free rotating compensator for above packing compression flange increases a set of spring, when there was a trace of wear packing, depending on the compression spring tension compensation, thus prolong product leak (leak time delay 3-5 years). When wear more than spring tension compensation amount, just pull the spring compression flange at the top of the nut can, do not need to repair, stopping air run, often not easy to produce leaks, which greatly improve the social and economic benefit of gas supply unit and gas. The product under the pressure of 4.0 Mpa compensation 5000 times don't leak, the sealing effect is superior.

Maintenance-free rotary expansion pipe material level difference

Maintenance-free rotating compensator and rotating compensator, flexible graphite packing is chosen by the level of nuclear level, industrial precision level respectively and maintenance-free rotating compensator in the packing adds some antioxidant ingredients (because of the company's commercial secrets, not for details) to delay the time of packing oxidation, so that maintenance free rotating compensator than rotating compensator sealing performance is greatly improved, make products to seal the leaking time delay.

Free maintenance of the rotary expansion process

Rotating compensator is processed seal standard parts and then pinched packing compression flange nut with a wrench. Its defect is: seal standard density has reached a certain value, plasticity is poor again. Not tight fit between sealing ring, prone to interlayer, among the seals in the packing chamber can't form a whole, and not enough because the wrench, packing will not be able to form a whole, so as to make the product sealing performance degradation. Because of steam or hot water has oxidation penetrate phenomenon to the packing, easy to leak.

Maintenance-free rotating compensator is the sealing material with pressure tools and molding first, forming density is not too close, keep the plasticity. Then the packing N times to product requirements (destiny) into the packing cavity, add some delay the composition of oxidation, then use hydraulic press second shaped under certain pressure (hydraulic press more than manual wrench in both strength and uniform process), between the packing ring, to improve the density of packing, the packing sealing performance better, make products to ensure no leak in 15 to 20 years.

To sum up, maintenance-free rotating compensator in product structure, material selection, technology compared with other types of rotating compensator are improved greatly, the performance of the product reliability and superiority.

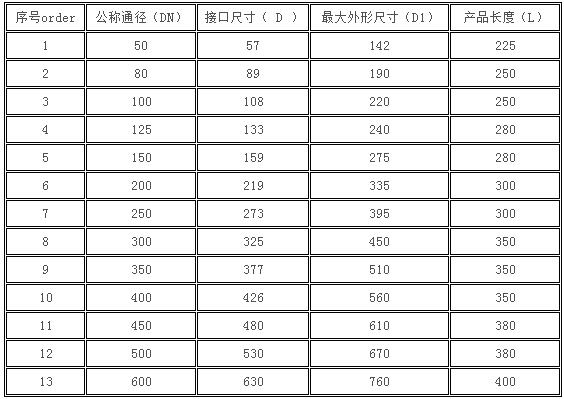

The technical parameters of rotary expansion without maintenance