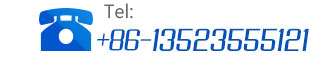

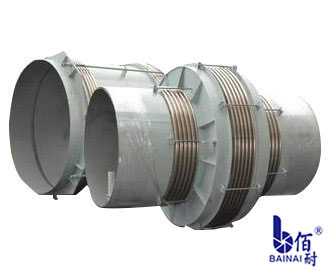

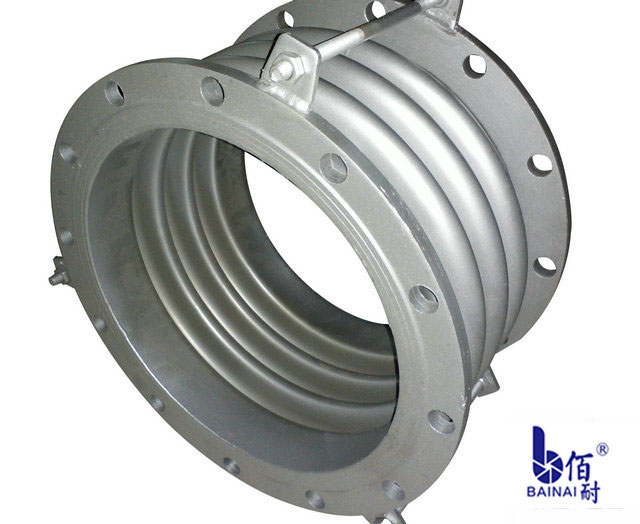

Non-metallic fabric compensator is mainly composed of non-metallic rings, heat insulation materials and steel structure. Non-metallic rings are made of non-metallic materials with excellent properties such as fibre fabric, silicone rubber and fluorine material. Its product strength, compensation amount, sealing, corrosion resistance and service life can be compared with similar products abroad. The products are comparable. The non-metallic fabric compensators produced by our company are widely used in flue ducts, ventilation ducts and projects requiring isolation and soft connection in electric power, metallurgy, environmental protection, cement building materials and petrochemical industries to replace imported products. It saves a lot of foreign exchange and achieves good economic and social benefits. The main characteristics of non-metallic fabric compensator are as follows: 1. Compensating thermal expansion: It can compensate multi-dimensional direction, which is much better than the metal compensator which can only compensate one-dimensional. 2. Compensation for installation error: Because the system error is inevitable in the process of pipeline connection, non-metallic fabric compensator can better eliminate installation error. 3. No back thrust, because the main material is non-metal, no thrust transmission. The non-metallic fabric compensator can simplify the design, avoid using large supports and save a lot of materials and labor. 4. Good resistance to high temperature and corrosion: The fluoroplastics and silicone materials have good resistance to high temperature and corrosion. 5. Good sealing: a relatively perfect production and assembly system, non-metallic fabric compensator is basically leak-free. 6. Light weight, simple structure, easy installation and maintenance. 7. The price is lower than the metal compensator, the quality is better than the imported products, the price is 1/3-1/5 of the imported products. Installation requirements for expansion joints of circular non-metallic fibre fabrics: 1. Flange bolts should be tightened gradually under uniform pressure, and all bolts should be as loose as possible. Spring washer can be added in addition to flattening pad to prevent loosening of nuts when using in harsh conditions. 2. Corresponding rubber asbestos gaskets should be selected according to working temperature between compensator and matching flat welded flange. 3. In the trial run, the compensator limit screw should be adjusted properly to facilitate product elongation and compression. 4. When the welded pipe is connected, the limit screw should be loosened properly to prevent the tension bending of the limit plate of the compensator or or the deformation of the product. 5. Cover the surface of rubber (fabric) to prevent slag damage during welding operation. Over the past few years, our Gongyi Hongsheng Pipeline Equipment Co., Ltd. has continuously developed new products, improved product quality, done a lot of research and experiments, put forward a new product structure, greatly improved the performance of the products, and won the praise of the vast number of users. If special specifications of products are needed, they can be designed and manufactured according to user's requirements. And sincerely hope that new and old customers, design units recommend the use of our company's products.