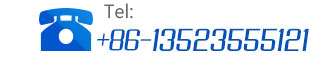

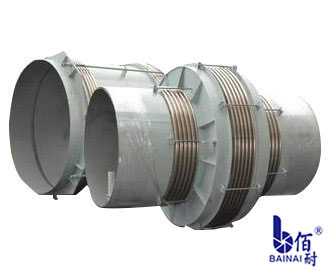

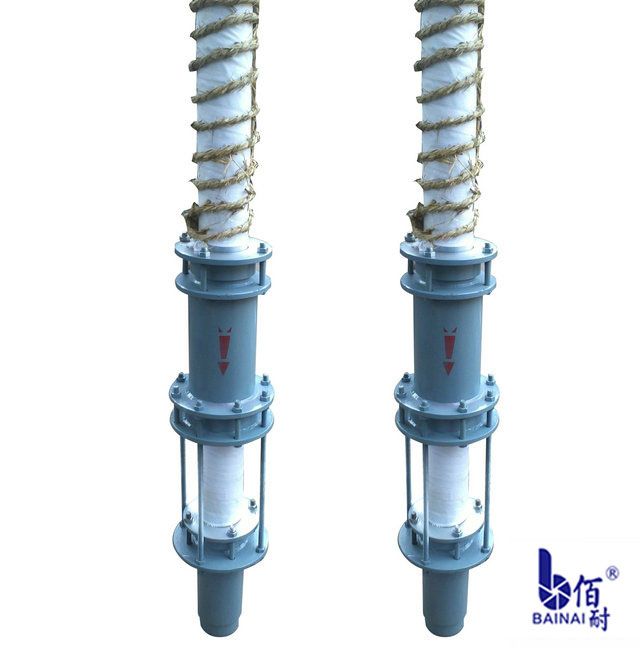

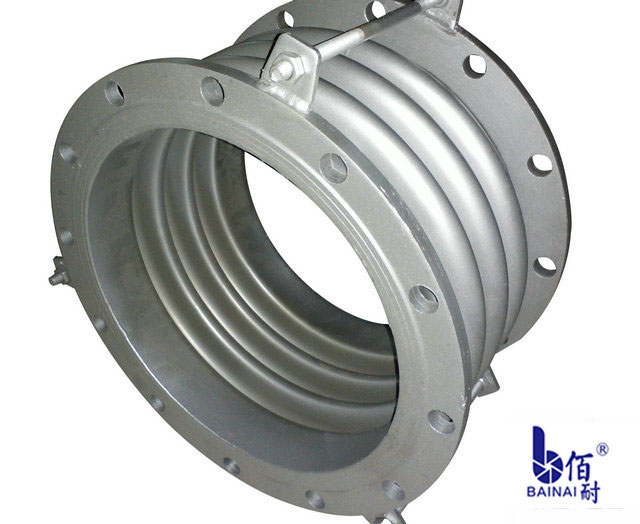

Corrugation compensator, also known as expansion joint, or expansion joint. The utility model is composed of a bellows (an elastic element) constituting the main body of the bellows and accessories such as an end pipe, a bracket, a flange, a conduit, etc. Mainly used in various pipelines, it can compensate for the thermal displacement of pipelines, mechanical deformation and absorption of various mechanical vibration, play a role in reducing the deformation stress of pipelines and improving the service life of pipelines. The connection mode of corrugated compensator is divided into flange connection and welding. Directly buried pipeline compensators are usually welded (except for trench installation). Axial compound corrugated compensator is also called axial expansion joint, axial compensator and axle compound corrugated expansion joint. This kind of expansion joint consists of two sections of bellows, short intermediate nozzle and long control rod. It only absorbs the axial displacement, and its long tie rod is a bearing member. The compensator is used for axial compensation, which has the characteristics of large amount of compensation and relatively economical. The compensator has nozzle connection and flange connection. The transverse large tie rod corrugation compensator of compound axial corrugation compensator can compensate the transverse displacement of bending pipe section and the angular displacement of small value. The large tie rod corrugation compensator is usually not used to compensate the angular displacement. The ripple compensator of large tie rod is composed of nozzle, two bellows and large tie rod. Large tie rod corrugation compensator can absorb transverse displacement in any plane of pipe system. The displacement spherical nut rotates around the spherical washer, and the tie rod of the large rod ripple compensator also has the ability to withstand internal pressure and thrust. Working temperature: <420 C Work pressure: 0.1 Mpa-2.5 Mpa Displacement direction: axial direction Path: DN32mm-DN700mm Notes for installation and use: 1. When the inner liner is installed, its direction should be consistent with the direction of the medium flow. 2. After field installation, the nuts on both sides of the ring plate shall be returned to the limit nut. Over the past few years, our Gongyi Hongsheng Pipeline Equipment Co., Ltd. has continuously developed new products, improved product quality, done a lot of research and experiments, put forward a new product structure, greatly improved the performance of the products, and won the praise of the vast number of users. If special specifications of products are needed, they can be designed and manufactured according to user's requirements. And sincerely hope that new and old customers, design units recommend the use of our company's products.官方下载3.jpg)