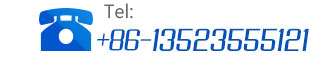

The heat supply network in urban residential areas is a secondary network of hot water pipes usually choose direct buried ripple compensator. See figure 1.

The directly buried corrugated compensator has anti-soil pressure, can self-guide, can achieve the same life as the directly buried pipeline, does not need maintenance and replacement, and has good bending resistance, can be installed directly on the pipeline as a part of the rigid pipeline. In hot water piping, many supports can be reduced to reduce the engineering cost. Especially in the city central heating network has occupied a considerable share.

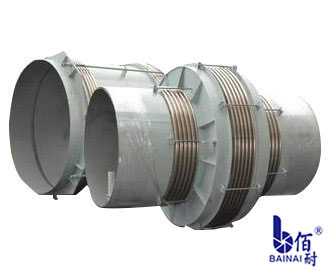

Compared with the direct buried corrugated compensator, the external pressure corrugated compensator has good bending resistance and can be installed directly on the pipe as a part of the rigid pipe

.jpg)

The compensator itself is equipped with drainage and drainage port, which can meet the requirements of high temperature (steam pipe network often starts and stops drainage and drainage, so the external pressure ripple compensator is widely used in high temperature (steam) pipe network intermittent heating. In addition, the bellows are stretched when the external pressure bellows compensator works. Due to this feature, compared with other types of axial compensators, the bellows have higher stability and can largely solve the instability problem of pipeline operation. Because of its inherent structure, it can greatly simplify and optimize the design of pipe network, and at the same time reduce the difficulty of engineering construction.

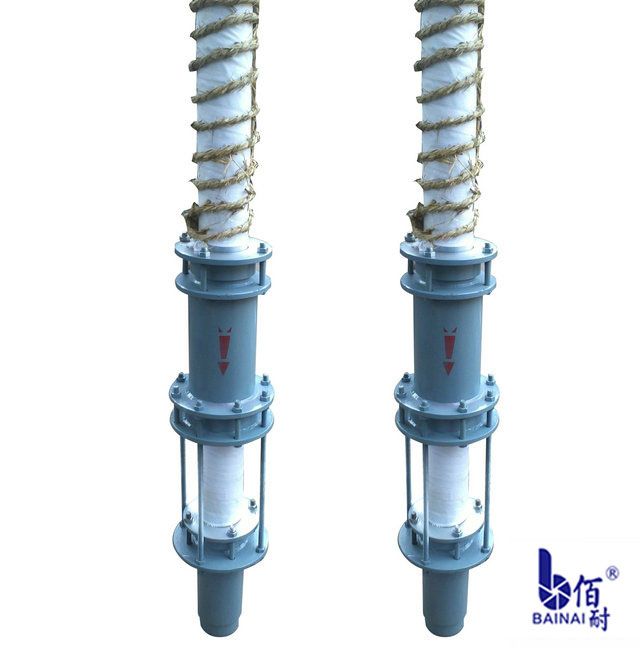

Buried ripple compensator and external pressure ripple compensator are different in different applications. For example, in the hot water network, the external pressure ripple compensator to replace the direct buried ripple compensator, in the pipeline compensation function is ok; However, the same diameter of the external pressure ripple compensator than the direct buried ripple compensator price is about 25% higher, not only that, the external pressure ripple compensator in the hot water pipe network does not reflect the characteristics and functions of the product, resulting in great waste of technology and function, which is a very economic, very unreasonable choice. The reasonable selection of ripple compensator plays an important role in the construction cost and the final safe operation.

4. Buried ripple compensation installation attention problems

(1) compared with the traditional cooking installation directly buried laying pipeline, directly buried pipeline after reaching enough length, friction between the pipe and the soil to prevent pipeline movement, the formation of anchor points (stagnation), have the effect of fixed support, save the pipe fixed support, thus make the directly buried pipeline laying low engineering cost, construction is convenient wait for a series of advantages.

However, due to the difference of pipe length and pipe heating, the anchoring point will be moved, and the compensation amount of corrugated compensator on both sides of the anchoring point will increase or decrease, bringing hidden danger to the pipeline operation.

Therefore, in some pipelines, the method of welding the wing plate will play the role of fixing the pipeline.

(2) the bellows compensator has been pre-pulled at the factory (the axial length of the compensator is the length of the design minimum temperature). During installation, the installation length of the compensator should be adjusted according to the installation temperature, and the shortened quantity should be adjusted.

Where, X is the axial compensation quantity;

Te is the installation temperature;

Tmx is the maximum operating temperature;

Tmin is the designed minimum operating temperature.

After installation, the pre-pull rod should be removed.

If put into use in the year after installation, there is no need to adjust, because the corrugated compensator is still left with a certain amount of tension after the factory pre-pull, there is enough margin to ensure the safety of the compensator.

The corrugated compensator that cannot be put into operation in the current year must be shortened by the above formula.

(3) after installation of corrugated compensator and piping, piping purge and system pressure test must be carried out.

The pipe shall be separated from the equipment without purge and pressure test by blind plate. Purge and pressure test shall be carried out after both ends are fixed with reliable installation.

If the section test pressure, section blind end is the time to fix the support, must take temporary reinforcement measures to avoid the fixed support is pushed down.

(4) the ripple compensator must be well protected during the system pressure test.

When the corrugated compensator does not have a pre-pull rod structure, it is necessary to do some accessories on the corrugated compensator to protect the corrugated compensator, so as not to pull bad corrugated compensator when the pipeline is tested.