1, the role of smoke duct

The function of the flue is to discharge smoke at the lowest pressure drop. The function of the air duct is to drop the air to the burner at the lowest pressure, and to make the air flow to the different burners as uniform as possible.

Smoke duct pressure reduction consists of two parts: pipe friction loss and pipe fitting local resistance loss, but the friction loss is much smaller than the local resistance loss. To reduce the key depends on the total pressure drop of pipeline to reduce the local resistance loss, local resistance loss is caused by the change of the velocity of the gas inside the tube, regardless of the change of the speed on the numerical, or change in direction, can cause local dynamic pressure loss, so the design and layout of the smoke duct, needs under the condition of the site allows to short, straight, prevent the bend and enlarge shrinks.

.jpg)

2. Layout principle of smoke duct

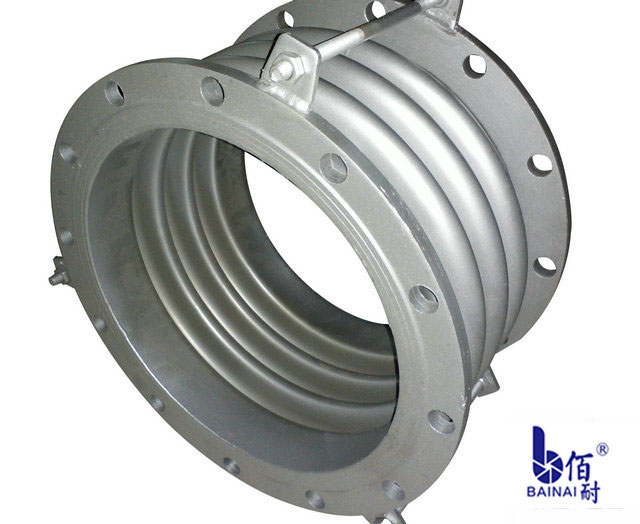

Under the premise of meeting the size requirements and location permission, the layout needs to be compact, the pipeline is short and convenient, the resistance of medium flow is small, and the inspection is convenient. The pipeline layout should be clear in hierarchy, neat and beautiful, keep the integrity and consistency, and not affect the passage, the operation and maintenance of surrounding equipment and pipelines. The two side extension pipelines need to be arranged symmetrically. Parts to be operated or maintained and all kinds of measuring holes shall be located in convenient places for operation and maintenance, and maintenance platforms or ladders shall be set up where necessary. The pipes shall be arranged in an sheltered place. For outdoor pipes, their surfaces shall be waterproof and drained. In order to absorb the stress during pipe operation, compensators should be installed in appropriate places. In order to evenly distribute the flue gas, the clear distance between the tail flue and the last convection tube should be greater than 0.6m[1].

3. Specifications and materials of smoke duct

Smoke duct section should be used in a circular, circular pipe inside the distribution of airflow is very uniform, resistance is not large, the structure is not complex, steel consumption is not much. Rectangular sections should be used when smoke ducts are connected to rectangular interfaces of burners, air preheaters, or fans, or when space is limited. The cross section of the rectangle should be close to the square, and the ratio of its short side to its long side should be greater than 0.4.

The smoke duct material usually USES Q 235-b.f, but for high altitude, the large-span pipe material needs to be used according to SH 3070. The thickness of the siding is usually 4 mm~ 5 mm in the air duct and 5 mm~ 6mm in the flue.

The smoke duct shall have good strength and stiffness, and the wind pressure, temperature and load during the design shall be implemented in accordance with relevant regulations. The design temperature is the maximum temperature of the pipe wall when the designed treatment capacity is operated normally and unfavorable conditions are considered. Structural calculation load is the sum of working load and additional load.

Use of steel, welding materials need to appearance inspection, can not have deformation, corrosion and damage, when the steel surface is pitting or scratches, problems such as the depth of it should be negative deviation. Half of the value is less than the thickness of the steel bolt, the steel structure welding material used, coating and lining materials need to have the quality documents, also accord with the requirement of design documents [2].

4. Turning structure and arrangement

4.1 do not use elbows with right angles

Use gentle bends where possible, or sharp curves with both sides curved. Avoid corners with right angles, especially those with right angles on the inside because of the resistance.

4.2 diffused and contracted elbows

A sharp bend, called a diffusion bend or a contraction bend, that changes the cross section of the flow when turning. It needs to have the same bending radius on the inside and outside, and you can usually take rn= rw≥ 0.3b. For smoke ducts that need to shrink after turning, using a contraction sharp bend instead (uniform section sharp bend) + (contraction pipe) can simplify the structure and reduce drag. However, for pipes that need to be diffused after turning, the diffused sharp bend should not be used, because its resistance is much greater than that of (uniform section sharp bend) + (diffusion tube).

4.3 size requirements for elbows in series

The pipe should be as far as possible to prevent the elbows directly connected in series, because the total resistance of the two elbows directly connected in series is much greater than the sum of the respective resistance of each elbow. If successive turns are required, ensure the length of the straight pipe as shown in FIG. 1 between adjacent elbows.

5. Fan inlet, bypass flue and chimney

5.1 fan inlet

Do not place elbows around the fan inlet to avoid reducing fan efficiency. If the position is limited, it is necessary to set up the inlet air chamber when turning from the inlet of the fan less than 3~ 4 times the equivalent diameter. The flow area of the inlet of the air chamber (A×B) can be calculated and determined by setting the inlet velocity at 13~ 15m/s, and the size of the inlet can be set as B: A= 2:1 ~ 3:1.

5.2 bypass flue

When the air preheater and induced draft fan are equipped with bypass flue, two layers of very strict regulation baffles should be set on the bypass flue, and the baffles should be set on the straight pipe section with very low flow rate and very uniform, so as to reduce air leakage during normal operation [3].

5.3 chimney entrance

Generally, there is only one chimney entrance. When it is necessary to open two entrances in special circumstances, relative distribution is required. In addition, a partition wall with a 45-degree Angle to the entrance center line of the flue should be set up inside the chimney to prevent two streams of smoke from hitting each other inside the chimney. The partition wall shall be higher than the top of the flue inlet, and the distance higher than the top of the flue inlet shall be greater than 1/2 of the height of the higher flue inlet, and greater than 0.5m.

6. Shunt and confluence structure

Where the smoke duct diverges or merges, the resistance is very high if the header is used to distribute or collect airflow. Therefore, when the number of branches of shunt or confluence is no more than 4, a tee or shunt with a small drag coefficient should be used.