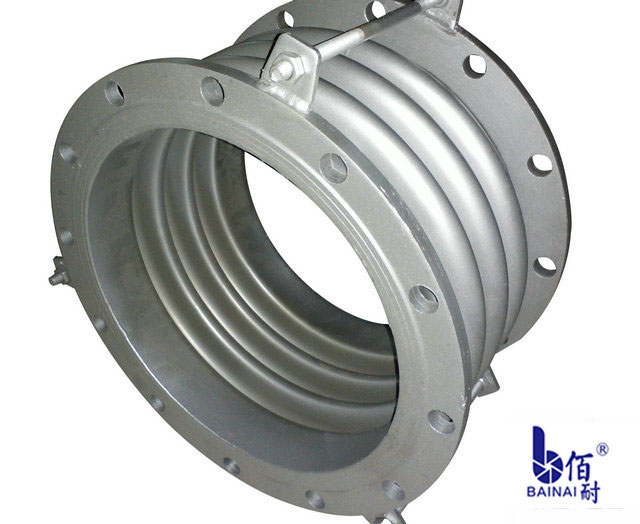

1/ appearance inspection of bellows expansion joint: welding size, whether there are welding defects, etc.;

The guarantee of welding quality is mainly to implement the process control of welding evaluation test conditions strictly.

First, can observe with the eye, see whether there are pores, residual welding slag;

Ii. Weld inspection can not only check the quality of the weld but also measure the height of the weld, which is an effective inspection method of zui.

Weld inspection standard:

Grade a, Ⅰ, Ⅱ weld must be the flaw detection, and should comply with the design requirements and construction and acceptance of norms, check the weld inspection reports.

Level 2, Ⅰ and Ⅱ weld shall not have crack, flash, burn through, such as arc pit defect. Ⅱ welds shall not be surface porosity, slag, arc arc pit, crack, scratch, grade and Ⅰ weld shall bite edge, welding defects such as full.

3. Even appearance of welding seam, smooth transition between welding bead and base metal, clean welding slag and spatter.

Iv. Surface pores:

1) Ⅰ, Ⅱ weld is not allowed; Ⅲ level every 50 mm length weld, allowed inside diameter of 0.4 t or less; And 2 stomata ≤3mm; Stomatal spacing ≤6 times aperture. Holdings bite edge: Ⅰ weld is not allowed.

(2) Ⅱ level weld: depth of 0.05 or less t bite edge, and 0.5 mm or less, continuous length is 100 mm or less, and on both sides of the bite edge total 10% or less of weld length.

(3) Ⅲ level weld: bite edge depth acuities were 0. Lt, and LMM or less.