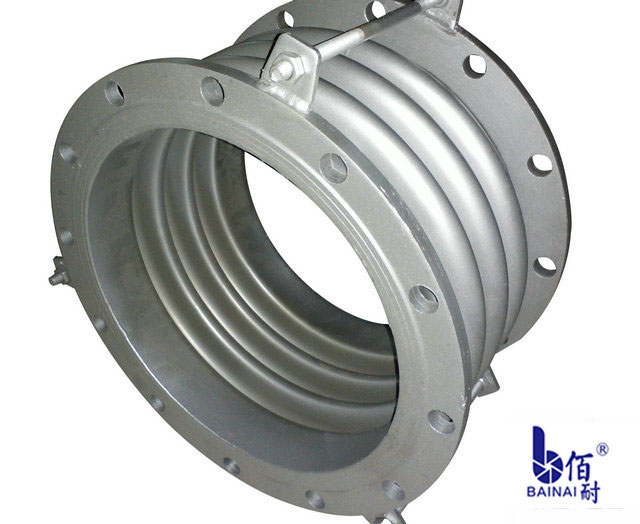

Manufacturing corrugated pipe material, at present, our country industry generally USES 18-8 austenitic stainless steel (such as OCr19Ni9, OCr19Ni11Ti, OCr17Ni12Mo2, etc.), and 300 series stainless steel (such as 304/316/321 respectively corresponding to China's OCr18Ni9, OCr17Ni12Mo2, 1 cr18ni9ti, etc.) because of its good plasticity, weldability and corrosion resistance and the strength of the performance, be the first choice of the industries manufacturing corrugated pipe materials. But they are sensitive to corrosion of chloride ion and sulfide, prone to pitting corrosion and intercrystalline corrosion, especially stress corrosion, which is also the cause of corrosion damage of bellows in oil refinery units. Throughout foreign manufacturing corrugated pipe material application, 18 - eight type austenitic stainless steel is still in the application in most operating conditions, but since the seventy s, in the refinery and chemical plants device of corrosive medium, such as, the use of the high temperature resistant, corrosion resistant Incoloy800, Inconel625 alloy instead of 18-8 austenitic stainless steel, can solve the problem of corrugated pipe corrosion damage, at present, As pipeline and bellows material, Incoloy800 alloy is widely used in nuclear power and certain amount of sulfide refinery gas, coal gasification, mineral combustion and other devices.

.jpg)

Cr: is the main element to improve the oxidation resistance and corrosion resistance of alloy. According to the rule of N/8, stainless steel material should contain 13, 17 and 28% Cr to have excellent corrosion resistance. Cr is easy to form stable oxidation film on the surface of material to prevent corrosion.

Ni: improve the oxidation resistance, general corrosion resistance and stress corrosion cracking resistance of the material, make the material have passivation ability in reducing medium, and increase the corrosion resistance of the material; In addition, it can maintain stable austenitic structure of the material, and make the steel have excellent toughness, processing and welding properties. The high nickel content prevents Cl stress corrosion.

Mo: high Mo components can increase the stress corrosion resistance of materials, and improve the pitting corrosion resistance and crack corrosion resistance. This is because Mo can accelerate the passivation process of Cr and timely repair the damaged parts of passivation film caused by Cl. Therefore, the stainless steel resistant to Cl corrosion needs to contain high Mo, but when the Mo content is high, it is easy to form brittle phase, so the Ni content needs to be increased.

Cu: enhance the passivation ability of Mo to ci-ni-mo stainless steel and improve the sulfur corrosion resistance of steel. Nb: it is a strong carbide forming element to avoid intercrystal corrosion caused by chromium carbide and poor chromium at grain boundary. In addition, it is helpful to improve the high temperature strength of materials.

C: the carbon content in steel should be as much as possible since the formation of carbides will lead to a decrease in corrosion resistance.

N: it has the function of stable austenite structure, its ability is 30 times of Ni, thus reducing phase, inhibiting phase formation and eliminating the reduction of thermoplastic and corrosion resistance caused by their formation.

Corrosion resistance characteristics of common bellows materials

1) according to the chemical composition of the material and the stress corrosion test results, the order of good and bad performance of stress corrosion resistance is: Inconel625 > fn-2 > Incoloy800 > b-315 > 316L > 304

2) pitting corrosion test results of 10%FeCl3 6H2O solution at 35℃ showed that the order of pitting resistance was Inconel625 > b-315 > fn-2 > 316L > Incoloy800 > 304

3) continuous polysulfuric acid corrosion test shows that: 304 can not withstand the corrosion of continuous polysulfuric acid, 316L stainless steel is sensitive to the corrosion of continuous polysulfuric acid, and Inconel625, b-315, FN -- 2 and Incoloy800 alloy is corrosion resistant to continuous polysulfuric acid.

4) intercrystalline corrosion resistance test shows that the order of intercrystalline corrosion resistance of the following materials is Inconel615 > FN -- 2 > b-315 >Incoloy800 >316L

.jpg)