When the pipe is pressed and heated, it will produce certain deformation, so the pipe design needs to improve its flexibility, and there are many ways to improve the pipe flexibility. The conventional way is to change the pipeline direction or spring hanger, but when the pipe diameter is large, the site is limited and the amount of compensation required is large, the expansion joint is adopted. The most common type of expansion joint is the bellows expansion joint. It is one of the components often used in the thermal compensation near the inlet and outlet of modern high-temperature pipelines and equipment.

Introduction to bellows expansion section

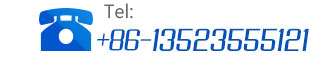

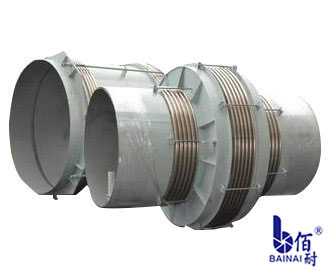

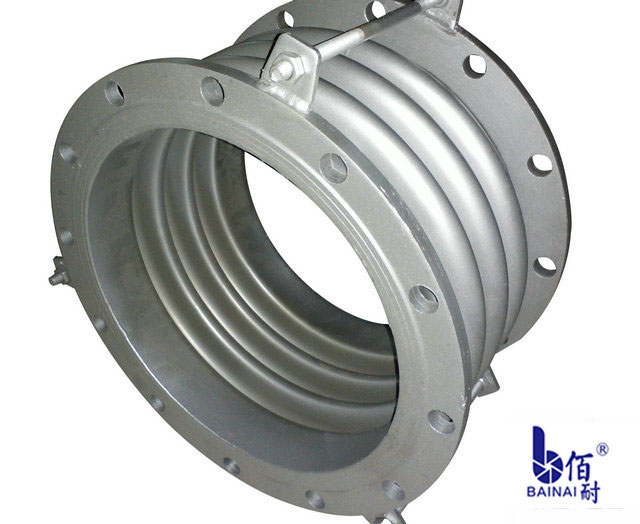

Bellows expansion joint is composed of one or several bellows and structural parts, which is used to absorb the size change of pipeline or equipment caused by thermal expansion and cold contraction. If large heat displacement is to be absorbed, several bellows expansion joints may be provided, and guide or fixing brackets may be provided if necessary. The bellows expansion joint has the advantages of large compensation capacity, small occupation area and strict structure, which is suitable for large diameter pipes with low pressure.

The type and selection of bellows expansion joint

(a) frequently used types. Single axial type, which is composed of bellows and structural parts, can absorb axial displacement, can not withstand the constraints of pressure and thrust; External pressure single axial type, which is composed of bellows and external pipe and end pipe structure that bear external pressure, can absorb axial displacement, can not bear the constraint of pressure and thrust; Single hinge type, which is composed of bellows and pin, hinge plate and vertical plate structure, can absorb the angular displacement in a single plane, can withstand the constraints of pressure and thrust; Single universal hinge type, composed of bellows and pin, hinge plate, universal joint and vertical plate structure, absorbing the angular displacement in any plane can withstand the constraints of pressure and thrust; With a single response is a complex structure, is composed of multiple single, middle connector connection, displacement absorption and the corresponding type of single, can withstand the pressure and thrust.

(2) steps for selecting expansion excerpts. First, the force on the pipe section is preliminarily analyzed to determine whether expansion joints need to be set on the pipe section. Second, the type of expansion joint is selected according to the force direction of the pipe segment. Thirdly, the thermal expansion displacement of the pipe segment is calculated, and the number of expansion joints on the pipe segment is selected according to the parameters of expansion joints. Fourth, carry out mechanical calibration.

.jpg)