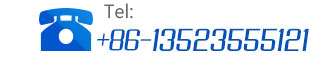

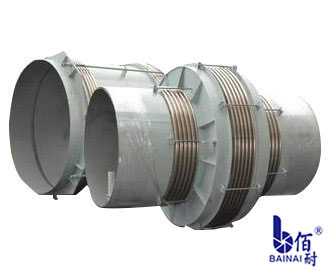

As a thermal compensation device, bellows expansion section can be compensation pipeline thermal deformation, the mechanical displacement and absorb the pipeline vibration, has simple assembly, good air tightness, cover an area of an area small, reliable operation, the advantages of large amount of compensation, in the aerospace, nuclear power, petrochemical industry, water conservancy, urban construction, electric power, metallurgy and other fields has been widely applied.

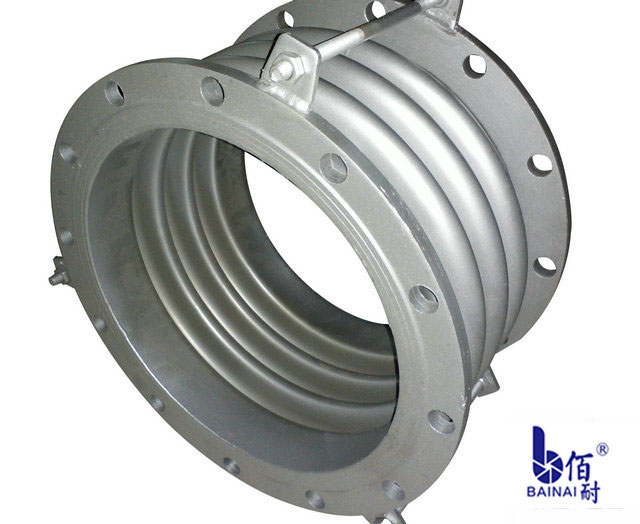

Check the fatigue life of bellows expansion joint

For the corrugated tubes of austenitic stainless steel, when usual R t s, the problem of low cycle fatigue is not considered. Otherwise, it is necessary to check the fatigue life. In GB16749-1997 austenitic stainless steel expansion joint in appendix A of displacement is according to the design temperature of 300 ℃, the fatigue damage number N = 4.5 x 10 4 times. Safety factor 15. Allowable cycles [N]=3000. When the design temperature of 300 ℃, the actual operation cumulative number of allowable cycle is equal to 3000 times, then we can choose according to appendix A lesser displacement. If not design temperature of 300 ℃ or actual need total allowable cycles is not equal to 3000 times (allowable cycles selection range of 50 ~ 5000 times). The displacement shall be corrected by A factor of C N or C t on the basis of the specified values shown in appendix A. When SW6 software is used for calculation, if the expansion joint is made of stainless steel, it is necessary to select whether the type of fatigue cyclic load is temperature difference cyclic load or mechanical cyclic load.

Fatigue life design of bellows expansion joint

It can be seen from the failure type and cause analysis of bellows expansion joint that the plane stability, circumferential stability and corrosion resistance of bellows are all related to its displacement, namely fatigue life. The stability and corrosion resistance of bellows will be decreased due to too low fatigue life. According to the previous test and experience, the fatigue life of bellows used in heating engineering should not be less than 3000 times.