The FSA with ASTM F1123

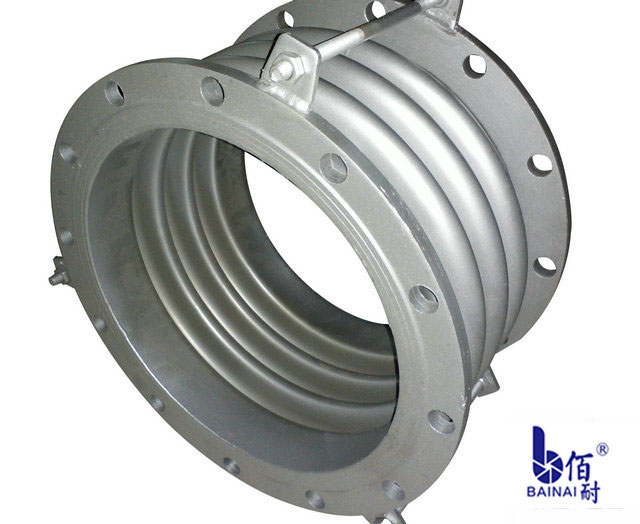

At present, there is no clear standard basis for rubber expansion joints in China. There are mainly two international reference standards, namely ASTM F1123, American society for materials and testing non-metallic expansion standard and FSA, American society for fluid sealing standard. EJMA expanded joint manufacturers association standard is mainly for metal expansion joint [1-2].

.png)

Comparison of current standards of rubber expansion joints at home and abroad

Rubber expansion joint parameters

The relationship between rubber expansion joints and ASME B31.3 after studying ASME B, it can be considered that rubber expansion joints are suitable for ASME piping system. In principle, it can refer to the use of "non-listed part" and the reference of metal expansion joints.

A304.7.2 indicates the guiding principles and standards for the use of unlisted parts. A304.7.2(A) allow the use of unlisted non-metallic part parts supported by "the part shall have extensive application experience and shall meet the successful experience of the same proportion, same or similar material and the same design conditions". A304.7.2(B) permits the use of parts not specified in ASME B31.3 that "pass performance tests under design conditions". A304.7.2(A) refers to the stress corrosion cracking of expansion joint joints. The rubber expansion joint does not have this kind of question, this is not the rubber expansion joint needs to consider the factor, may omit its request. (B) consideration shall be given to the media and its compatibility with the materials of production. (C) relation between minimum layer thickness of expansion joint and fatigue life. Fatigue damage is not a factor in the consideration of rubber expansion joints as they do not show a endurance limit. Therefore, thickness is only a property of holding pressure. (D) operability in relation to maintenance and installation. Rubber expansion joints are no different from metal expansion joints. (E) seals shall be considered. The rubber expansion joint is flanged. (F) specifications requiring installation procedures and shipping information. Similar to (D), the same as the metal expansion joint. Section (G) lists 10 design criteria that can be requested from the manufacturer of expansion joints. The 10 items listed are all standard information for any type of expansion joint, metal or nonmetal.

Comparison of current standards of rubber expansion joints at home and abroad

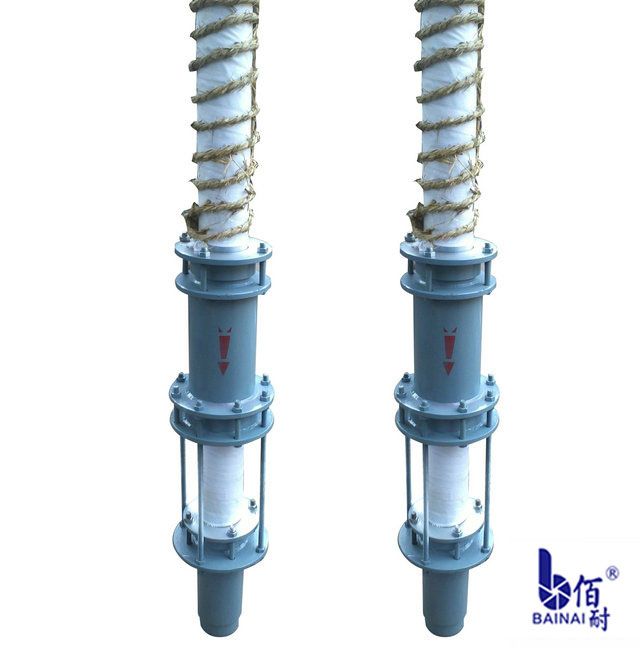

Rubber expansion joint

From this information, it can be concluded that the rubber expansion joints can be applied to ASME B31.3 process piping requirements. They are suitable for the requirements of "non-listed parts", and their performance parameters even exceed those of metal expansion joints [3].