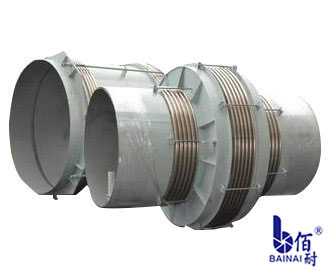

& does relevant recommendations: rigid waterproof casing, rigid waterproofing casing is sell like hot cakes gongyi city full state pipeline equipment co., LTD. The main business of our company has been made as a special equipment manufacturing license and ISO quality management system certification of qualified companies, the company management concept: the factory in order to "customer needs is our goal" principle, wholeheartedly for the customers with excellent products, reasonable prices, fast delivery cycle, professional technical support and perfect after-sales service. In the future, full state is full of confidence and hope, was determined in a more high quality brand and good service, sincere cooperation with customers at home and abroad, to do the northern area of the thermal compensation smoke duct equipment industry's first brand.

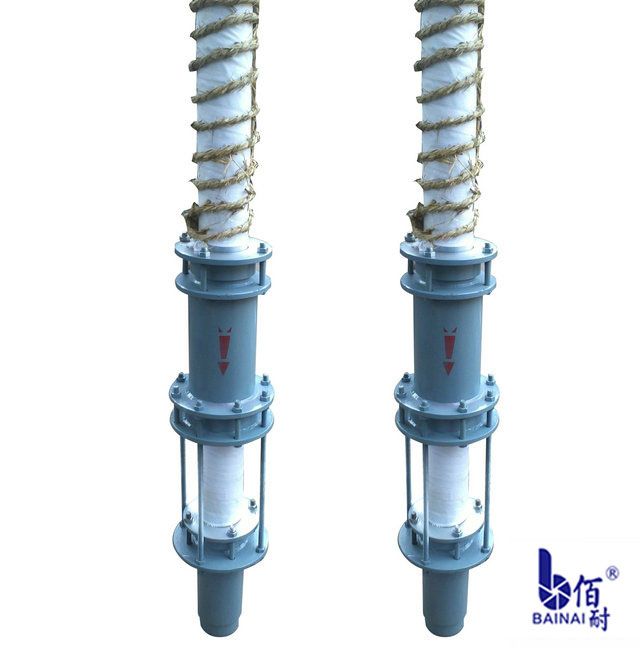

The introduction of rigid waterproofing casing

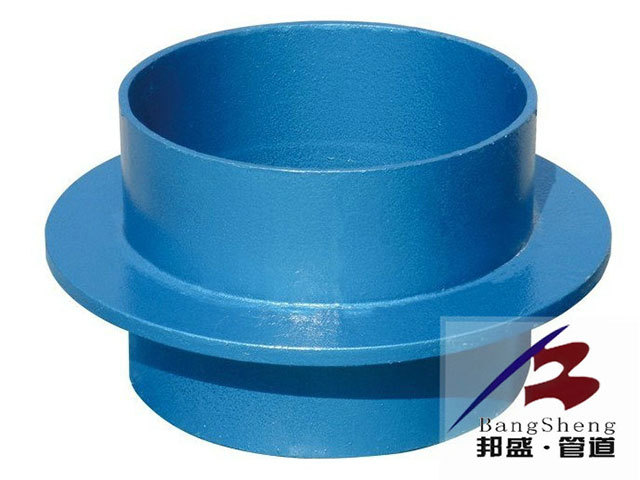

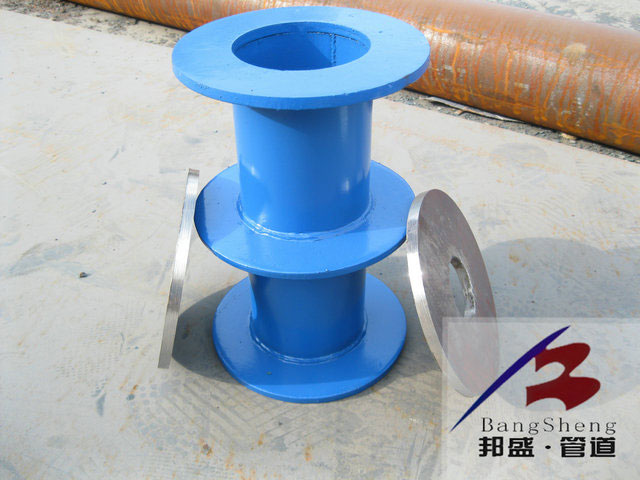

1. S312 rigid waterproof type I and type II water casing pipe, apply to the cast iron pipe, can also be applied to nonmetallic pipe, but should be used according to the wall thickness of pipe fixed on size.

2. Wing ring and steel bushing processing is completed, both in its outer wall paint again remember including ZhangDan or cold seed oil (primer).

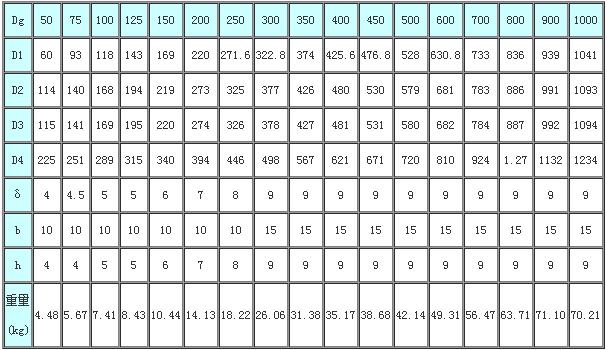

3. Type I water pipe in the wall thickness is equal to or only make one or both sides wall thickening for cast iron welding wheel length required for use.

4. Type II waterproof casing size listed in the table material weight steel casing (sleeve length L value calculated at 200 mm) and the weight of the wing ring. Steel casing and wing ring made of A3 material, T42 electrode welding.

5. Type I and type II casing wall outside the wall, in case of the concrete wall should be switched to the concrete wall, its pouring concrete walls should be switched to the concrete wall, its range of pouring concrete, type I casing is bigger than cast shovel by wheel diameter is 300 mm, type II casing should be colorful ring (D4) large 200 mm in diameter, and must be poured casing a fixed in the wall. Packing should be closely compacted casing.

6. Type II water jacket of the concrete wall thick, should not be less than 200 mm, or one or both sides should make wall thickening. Increasing the diameter of the part, the minimum should be colorful ring (D4) large 200 mm in diameter. Type I upset the diameter of the part should be than the big wheel diameter 300 mm.

The main technical parameters of rigid waterproofing casing